#Vehicle Exhaust System Component

Explore tagged Tumblr posts

Text

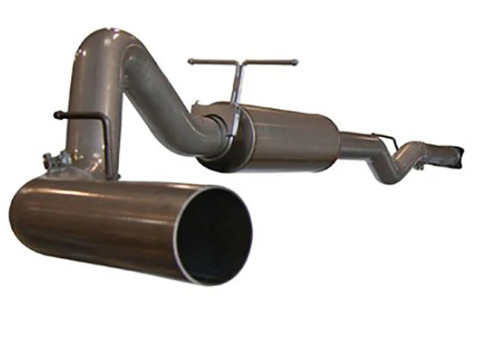

Powerful Vehicle Exhaust System Components.

Flaunt your vehicle's power by installing a Powerful Vehicle Exhaust system component that brings the crazy sound of your engine. At AutoPartsUSA, we have numerous vehicle exhaust systems from top brands. So, explore our website to get the best deals on exhaust components. Shop now.

0 notes

Text

1957 Chevy

The Legendary “Black Widow” 1957 Chevy: A Piece of Racing History

When it comes to legendary cars, the 1957 Chevrolet, also known as the “Black Widow,” holds a special place in the hearts of car enthusiasts. However, few people know the intriguing story behind this iconic vehicle. In this article, we will take you on a journey through time and explore the fascinating history of the Black Widow.

The Secret Support Behind the Scenes

In the 1950s, car manufacturers were prohibited from directly promoting racing. Nevertheless, behind closed doors, Chevrolet found a way to support the racing community. They collaborated with a company called SEDCO to build a limited number of race-ready 1957 Chevys. Only 18 of these incredible vehicles were ever produced.

Unleashing the Beast

To create the ultimate racing machine, Chevrolet started with the lightest model available, the no-frills 150 utility sedan. They then equipped these cars with high-performance drivelines that would leave their competitors in awe. The Black Widows proved to be astonishingly fast, setting records and securing multiple victories on the track.

Restoring the Legend

One particular Black Widow has undergone an extensive body-off-frame restoration, meticulously recreating its original glory. The attention to detail is impeccable, resulting in a pristine body that is arguably even better than when it first rolled off the factory floor.

Exquisite Exterior

Painted in the iconic Black Widow colors of Onyx Black and India Ivory, the exterior of this restored beauty is nothing short of breathtaking. Every panel is laser straight, and the gaps are precise. There isn’t a hint of rust or damage to be found. The flawless paint job has been polished to a mirror-like finish, allowing you to see your own reflection. It’s like holding history in your hands.

Interior Simplicity

Inside the Black Widow, you’ll find a minimalist design that emphasizes performance over luxury. There are no frills, not even a back seat! The rear windows are stationary, and amenities such as armrests, visors, and even a dome light are absent. However, this simplicity only adds to the car’s authenticity and racing pedigree.

Attention to Detail

No aspect of the Black Widow’s restoration has been overlooked, including the trunk compartment. Painted in glossy white, it exudes cleanliness and attention to detail. A reproduction mat, seat divider, and weatherstrip have been added to complete the authentic look. Even the spare tire matches the original style with its 6 lug pattern and reproduction Firestone tire.

The Heart of a Champion

Under the hood lies a highly detailed engine compartment that exemplifies show-quality craftsmanship. The 283 cubic-inch V8 engine has been built to its original 283 horsepower specifications, complete with a correct factory fuel injection setup. Not only does it look stunning, but it also performs flawlessly. With a responsive throttle and a distinctive idle, this powerhouse truly embodies the spirit of a race car.

A Masterpiece Underneath

The detailed restoration extends to the underside of the car as well. The chassis has been meticulously prepped and painted in a smooth gloss black finish. Every component has been rebuilt, replaced, restored, and detailed to match the original specifications. The Black Widow features front and rear sway bars, as well as the unique duplication of two shocks at each rear wheel for enhanced performance.

A True Muscle Car

With its completely rebuilt brake system, all-new fuel system, and Flowmaster dual exhaust, this Black Widow not only looks and sounds like a classic muscle car but also performs like one. The spotless Chevy Orange engine block, lower plug wire shielding, canister-type oil filter, restored starter, and dated 1957 transmission all contribute to creating an authentic driving experience. The floors, braces, and rockers have been meticulously restored to their original factory red oxide primer finish.

101 notes

·

View notes

Text

Achieving a goal is the beginning of a new challenge. To run really fast, HKS thinks.

A drag race scene where people compete for 0.001 seconds over a distance of about 400 meters in just a few seconds. '91 is a drag field that demands quick response and power from the engine, clutch, suspension, and even a single drop of oil or gasoline, as well as durability and transmission ability to handle instantaneous high power. -In '95-'96, the ``HKS R32 DRAG GT-R'' won the series championship in the RRC Drag Race Championship for three consecutive years. The following year, in 1997, the ``HKS DRAG 180SX'' in the BERC Drag Race Championship Pro Stock class and the ``HKS R33 DRAG GT-R'' in the Pro GT-R class achieved the Avec Championship. Having achieved one goal in 1997, what we aimed for in 1998 is:

Quarter mile time in 9 seconds with FF base vehicle. They then talked about their know-how from drag racing to date, and ``HKS FF DRAG CELICA'' made its debut. The first goal was achieved on October 9, 1998 at Sendai Highlands with a time of 9.886 seconds. He further improved his time to 9.727 seconds, and in 1999 he set a goal of breaking the quarter mile in the 6-second range, and has already begun a new challenge. "Achieving a goal is the beginning of a new challenge" - HKS' never-ending battle continues

HKS

■Company overview

●Name HKS Co., Ltd. Established October 31, 1971

●Capital 607,475/Kawa Representative Director and President Naruyuki Hasegawa

●Location Head Office 2266 Kamiogawa, Kunikami City, 418-0192

●Business details

Development, design, and product sales of automobile parts, racing engines, turbocharger-related parts, and automotive components and systems Design, development, and manufacturing of original mufflers, suspensions, and engine parts Development of complete cars, development of aircraft engines

●Number of employees: 407 (333%, 74 women)

●Equipment overview

Experiment building: Dynamometer (1,000/800/600~300/200/PS) Chassis dynamo, exhaust gas analyzer

Old experimental building: Dynamometer (600/600-500-200/PS)

Manufacturing factory: 10ft machining center, 5 NC lathes, 41 cam polishing machines, 21 biston narai, 11 turning centers, 21 crank Kenjoshi, Monzen Kendanmei, 21 surface grinders, 1 gun drill machine.

Muffler factory: Pipe bender, robot welding machine, 1 laser machine, shell machine, multi-spot welding machine 11, 100T press, TIG welding machine, CO2 welding machine multi-stage

Muffler 2nd factory: Pipe bender / shirring / Yasuda machining center 1 piece

Suspension factory: Cold solid coiling machine, continuous coiling machine, surface grinding machine, shot peening machine, automatic setting machine, automatic load testing machine, etc.

●Affiliated companies

HKS Aviation Co., Ltd. HKS Service Center (Tokyo/West/Kyu)

HKS USA, INC (USA)

HKS EUROPE()

25 notes

·

View notes

Text

Military Armed Forces The M1A2 Abrams Main battle tank. M1A2 (Baseline) : Production began in 1986 and entered service in 1992 (77 built for the US and more than 600 M1s upgraded to M1A2, 315 for Saudi Arabia, 218 for Kuwait). The M1A2 offers the tank commander an independent thermal sight and ability to, in rapid sequence, shoot at two targets without the need to acquire each one sequentially, also 2nd generation depleted uranium armor components. M1A2 SEP (System Enhancement Package) : Has upgraded third-generation depleted uranium armor components with graphite coating (240 new built, 300 M1A2s upgraded to M1A2 SEP for the USA, also unknown numbers of upgraded basic M1s and M1IPs, also 400 oldest M1A1s upgraded to M1A2 SEP) M1A2 SEPv2 : Added Common Remotely Operated Weapon Station as standard, color displays, improved interfaces, a new operating system, improved front and side armor with ERA (TUSK kit), tank-infantry phone as standard, and an upgraded transmission for better durability. M1A2C (SEPv3) : Has increased power generation and distribution, better communications and networking, new Vehicle Health Management System (VHMS) and Line Replaceable Modules (LRMs) for improved maintenance, an Ammunition DataLink (ADL) to use airburst rounds, improved counter-IED armor package, improved FLIR using long- and mid-wave infrared, a low-profile CROWS RWS, and an Auxiliary Power Unit (APU) under armor to run electronics while stationary instead of the engine, visually distinguishing the version by a small exhaust at the left rear. Prototypes began testing in 2015, and the first were delivered in October 2017. Fielding is expected to begin in 2020. M1A2D (SEPv4) : Under engineering development with delivery planned to start by 2020. The Commander’s Primary Sight, also known as the Commander’s Independent Thermal Viewer, and Gunner’s Primary Sight will be upgraded with 3rd Gen FLIR, an improved laser rangefinder and color cameras. Additional improvements will include advanced meteorological sensors, laser warning/detection receivers, directional smoke grenade launchers and integration of the new XM1147 multi-purpose (AMP) 120 mm tank round. The AN/VVR-4 laser warning receiver and ROSY rapid obscurant system have been trialed by the US Army for adoption on the Abrams tank and Bradley fighting vehicle.

10 notes

·

View notes

Text

Seamless Mild Steel Tube At Lowest Price

Seamless mild steel tubes are a key component in numerous industrial applications due to their unmatched strength, durability, and ability to withstand high pressure. Whether you’re working in the construction industry, automotive sector, or manufacturing pipelines for oil and gas, seamless mild steel tubes provide reliability and performance.

What is a Seamless Mild Steel Tube?

A seamless mild steel tube is manufactured without any welding seams, making it exceptionally strong and resistant to corrosion. The absence of seams means the tube can handle higher pressure and is more uniform in structure, providing superior integrity and strength compared to welded tubes.

Benefits of Seamless Mild Steel Tubes

Strength and Durability: Seamless mild steel tubes are known for their robustness. Their lack of seams eliminates the weak points found in welded tubes, making them perfect for high-pressure applications.

Corrosion Resistance: Mild steel naturally resists corrosion, and seamless tubes offer an added level of protection in environments where exposure to chemicals or water is common.

Smooth Finish: Seamless tubes have a smooth internal and external finish, which not only enhances their aesthetic appearance but also improves fluid or gas flow, making them highly efficient in industries like oil and gas.

Versatility: These tubes can be used in a wide variety of industries, including automotive, construction, industrial equipment, and more. They are often used in pipelines, boilers, and mechanical systems.

Higher Pressure Tolerance: The seamless structure allows these tubes to withstand higher pressure, making them suitable for applications where strength and safety are paramount.

Applications of Seamless Mild Steel Tubes

Automotive Industry: Seamless mild steel tubes are widely used in vehicle components such as frames, shock absorbers, and exhaust systems due to their durability and strength.

Oil & Gas Pipelines: The oil and gas sector heavily relies on seamless tubes for high-pressure pipelines because of their ability to handle extreme temperatures and pressure.

Construction: In construction, seamless mild steel tubes are used for building frameworks, scaffolding, and support structures due to their load-bearing capabilities.

Boilers and Heat Exchangers: These tubes are ideal for high-temperature and high-pressure environments, like boilers and heat exchangers, where materials must withstand continuous stress.

Udhhyog: Your Trusted Supplier for Seamless Mild Steel Tubes

If you’re looking for reliable and high-quality seamless mild steel tubes, Udhhyog is your go-to partner. Udhhyog is a technology-driven platform that aims to simplify procurement for businesses across industries. They offer a wide range of products, including MS seamless pipes, flanges, and valves, ensuring you get the best quality materials at competitive prices.

At Udhhyog, you can find a wide selection of seamless mild steel tubes that meet stringent industry standards, providing the strength, durability, and performance your projects require.

Explore Udhhyog’s seamless pipe offerings here.

Whether you’re working on a high-pressure pipeline, building a skyscraper, or manufacturing automotive components, seamless mild steel tubes are the backbone of any project that demands strength, durability, and reliability. Partnering with suppliers like Udhhyog ensures you get quality materials that will last for years to come.

Why Choose Seamless Mild Steel Tubes?

By opting for seamless mild steel tubes, you are investing in long-term performance. Their strength, resistance to corrosion, and seamless design make them an indispensable choice for industries that rely on high-quality materials for critical applications.

#SeamlessMildSteelTube#MildSteelTubes#SteelTubeSupplier#SeamlessPipes#IndustrialTubes#Udhhyog#PipeSupplier#MSSeamlessTube#ConstructionMaterials#OilAndGasPipelines#AutomotiveIndustry#HighPressureTubes#DurableTubes#SteelProducts#B2BProcurement

4 notes

·

View notes

Note

went to a sim racing facility for the first time!! having never raced or driven in my life, I set a somewhat ok 58.1 in a Fiat Abarth 500 Assetto Corsa around Brands Hatch Indy.

In honor of this, do you have any Fun Fiat Facts?

Whipped out me sim rig to find out how good a time that was, and it must have taken me around ten laps to manage less (a 57.8)! (Gamer excuses for this sessions are a framerate barely at illusion-of-movement levels and some clutch mapping issue that made most shifts crunch.) For someone who never even drove, that's quite good! Now, maybe not "Run get a sim wheel right now for the good of humanity" good... but maybe "Finding out a used Logitech G25 is Christmas-present cheap may enrich your free time" good.

As for the Fun Fiat Fact request, it's denied: not only because I've already written about Fiat -and for my very first post no less- but most importantly because that car is not a Fiat! Indeed, since 2007 Abarth is, officially, a brand unto itself, that sells models like the 500 and the 124, just like Fiat sells models like the 500 and the 124. Now, I don't think anyone is going to try and pretend the similarities are just a coincidence or that an Abarth 500 is in any way not objectively a Fiat - but it's not a "Fiat 500 Abarth" any more than the one below is a "Chevrolet Cavalier Toyota".

That's right, there once was such thing as a Toyota Cavalier. Oh, brand engineering.

This is a rare but not completely isolated arrangement - see for example Ruf, German brand that makes vehicles based on Porsches, best known for the Ruf CTR -nicknamed "Yellowbird"- that bested the Ferrari F40's incredible top speed record.

Be careful who you call ugly under the 200mph barrier.

But yeah, all that is to say, I am not going to give you any fun Fiat facts. >:(

Let's give you fun Abarth facts then! Let's talk about fake exhausts. Big engines move a lot of gas -that's kind of the point- so they have big exhaust pipes for all that gas to leave, and high-tier exhausts are made of fancy materials that shine.

This -and our love for fancy shiny things in general- makes people like big shiny exhausts. But exhausts are very long, and making them big and shiny is costly. So people figured, what if we only make it wide at the end, where you actually see it?

After all, if the tip is large enough, it will satisfy regardless of what the rest of its length is like - sure, people may think it looks a bit weird when you take it out, but that only happens by the time you've already scored, doesn't it. But now, back to exhausts.

If you can just attach a bigger tip to the end of your exhaust, surely you can attach a tip of a different material and have a bog standard exhaust with a cool shiny tip, that now you can also shape to your designer's content!

(Fun fact: an aftermarket exhaust system that only replaces the components that come after the catalytic converter -which, contrary to the popular misconception that confuses it with the muffler, is mounted right beside the engine- is called a "catback exhaust". Picture unrelated.)

But then, if the tip material is completely separate from the exhaust pipe, you can now just make it a plastic part of the bumper and it doesn't need to withstand temperatures as high and is even cheaper and easier to style!

And now that they're not mounted on the tip of the exhaust, they don't have to coincide with it, so you can split the exhaust into two tips, which is cooler because they're more! Hell, you can also do that by just making the exhaust coincide with one tip and have the other blanked off!

But at that point, why even have the exhaust show up back there at all? Just make the tips blank and make the exhaust go down behind them!

And at that point why not just fuck it up to the point where you need this exhaust evolutionary biology 101 course to even recognize it is meant to be an exhaust, if we can kill God who's left to stop us from dancing on his corpse.

Well, the Abarth 500, as you might have guessed by now, has fake exhaust tips. But here's the weird thing: the real exhaust tips are not any less shiny and prominent than the fake ones. See for yourself in this sound video.

youtube

Oh also, I hope the devil got some killer stuff from the deal he made with the Abarth exhaust engineer, because if he only got a piddly little soul in exchange for the ability to turn 500 engine noise into this he got majorly screwed over.

Links in blue are posts of mine explaining the words in question - if you liked this post, you might like those!

15 notes

·

View notes

Text

ASM Performance Cars is a UK-based company specializing in high-performance and modified vehicles. Their offerings include a wide selection of performance cars such as BMW, Audi, and Subaru, which cater to enthusiasts looking for exceptional driving experiences. The company provides various modifications, from tuning and engine upgrades to custom exhaust systems, ensuring that each vehicle can deliver top-tier performance on the road.

ASM is not just about selling performance cars; they also offer advice and FAQs to guide owners and buyers through essential topics such as car maintenance, tuning, and how to improve car reliability. They emphasize the importance of regular servicing, maintaining high-quality components, and utilizing premium fuel for optimal performance. For those interested in enhancing their vehicle’s capabilities, ASM provides insights into engine tuning, brake and suspension upgrades, and other performance mods.

For more information, you can visit their website at asmperformancecars.co.uk to explore their inventory or get tips on performance upgrades.

3 notes

·

View notes

Text

From Engine to Electronics: Proper Diagnostic Techniques for Resolving Maserati Problems

Maserati, the epitome of Italian luxury and performance, is renowned for its stylish design and high-performance capabilities. However, like any high-end vehicle, Maserati can encounter a range of issues, from engine troubles to electronic malfunctions. Proper diagnostics is crucial in maintaining the health and performance of these sophisticated machines. This article will guide you through the common problems Maserati face and the proper diagnostic techniques to resolve them.

Common Maserati Problems

1. Engine Issues

Maserati engines are marvels of engineering, but they can develop problems over time. Common engine issues include:

Misfires and Rough Idling: This can be caused by faulty spark plugs, ignition coils, or fuel injectors.

Overheating: Often due to a malfunctioning cooling system, such as a failed water pump or a clogged radiator.

Oil Leaks: These can originate from various seals and gaskets, leading to low oil levels and potential engine damage.

2. Transmission Problems

Maserati transmissions are designed for performance but can experience:

Slipping Gears: This could indicate worn-out clutch plates or issues with the transmission fluid.

Delayed Shifts: Often due to problems with the transmission control module or low fluid levels.

3. Electrical and Electronic Failures

Modern Maseratis are equipped with advanced electronics that can sometimes fail, including:

Dashboard Warning Lights: These can indicate issues ranging from simple sensor failures to serious engine problems.

Infotainment System Glitches: Problems with the touch screen, navigation, or audio system are not uncommon.

Diagnostic Techniques

1. OBD-II Scanner

The On-Board Diagnostics II (OBD-II) scanner is an essential tool for diagnosing Maserati problems. It can read error codes from the car's computer, providing insight into various issues.

How to Use: Connect the OBD-II scanner to the port located under the dashboard. Turn on the ignition and follow the scanner’s instructions to retrieve the error codes.

Interpreting Codes: Each code corresponds to a specific problem. For example, P0300 indicates a random/multiple cylinder misfire, while P0128 points to a coolant thermostat issue.

2. Visual Inspection

A thorough visual inspection can reveal obvious issues such as leaks, damaged components, or worn-out parts.

Engine Bay: Check for oil leaks, loose connections, and the condition of belts and hoses.

Undercarriage: Inspect for fluid leaks and damage to the exhaust system.

Electrical Connections: Look for corroded or loose battery terminals and wiring issues.

3. Multimeter Testing

A multimeter is useful for diagnosing electrical issues in a Maserati.

Battery Voltage: Measure the voltage across the battery terminals. A healthy battery should read around 12.6 volts when the car is off and around 14 volts when running.

Sensor Checks: Test various sensors, such as the oxygen sensor or mass airflow sensor, to ensure they are functioning correctly.

4. Compression Test

A compression test helps diagnose internal engine problems such as worn piston rings or valves.

Procedure: Remove the spark plugs and insert a compression gauge into each cylinder. Crank the engine and note the pressure readings. Low or uneven readings indicate internal engine issues.

5. Professional Diagnostic Tools

Maserati dealerships and specialized repair shops use advanced diagnostic tools that can access proprietary systems and provide more detailed information.

SD2/SD3 Diagnostic Systems: These are specialized tools used by Maserati technicians to diagnose and program vehicle systems accurately.

Diagnostic Software: Tools like Xentry or PIWIS can interface with Maserati's electronic systems for comprehensive diagnostics.

Addressing Common Issues

1. Engine Repairs

Misfires and Rough Idling: Replace faulty spark plugs, ignition coils, or fuel injectors. Regular maintenance and using high-quality fuel can prevent these issues.

Overheating: Ensure the cooling system is functioning correctly by checking the water pump, radiator, and thermostat. Flushing the coolant system periodically is also recommended.

Oil Leaks: Identify the source of the leak and replace the necessary seals or gaskets. Regularly check oil levels and change the oil according to the manufacturer's recommendations.

2. Transmission Solutions

Slipping Gears: Inspect and replace worn clutch plates and ensure the transmission fluid is at the correct level. Consider a fluid change if necessary.

Delayed Shifts: Diagnose and repair issues with the transmission control module or solenoids. Regular transmission servicing can prevent many of these problems.

3. Electrical Fixes

Dashboard Warning Lights: Use an OBD-II scanner to identify and address the underlying issue. Reset the warning lights after repairs are completed.

Infotainment System Glitches: Perform software updates and check for any loose connections or faulty components. In some cases, a complete system reset may be required.

Conclusion

Proper diagnostics are essential for maintaining the performance and reliability of your Maserati. By using the right tools and techniques, you can identify and resolve issues promptly, ensuring your luxury car continues to deliver the driving experience it was designed for. Regular maintenance and timely repairs are key to keeping your Maserati in top condition, from the engine to the sophisticated electronics.

#maserati car#maserati car diagnosis#maserati service center#maserati car maintenance#maserati car mechanic

2 notes

·

View notes

Text

Ferrari unveiled the '296 Challenge' at the Finali Mondiali race at Mugello Circuit. The car is scheduled to debut in the Ferrari Challenge in the 2024 season and is the ninth model in the history of the single-make championship hosted by Ferrari. The Ferrari Challenge is currently in its 32nd season.

As riders around the world became more skilled and competitive, the 296 Challenge attempted to make bigger changes than the original model. The 296 Challenge continues Ferrari's long tradition of developing cars for gentleman drivers, but draws on the expertise accumulated in the '296 GT3' more than any other model. The 296 Challenge is a vehicle for drivers who are passionate about future GT racing. During the development of the 296 Challenge we made significant changes, not just minor changes to the model of the production car, but to make it a vehicle optimized for track driving. An extreme form of the vehicle was developed that improves overall performance while maintaining consistency and repeatability for testing and competition.

The 296 Challenge is the first car in Ferrari's single-brand range to be equipped with a V6 engine. So far, all models participating in the Challenge have been equipped with V8 engines. The biggest change compared to the 296 GTB is the elimination of the hybrid powertrain like the 296 GT3. As a result, while reducing the weight of the vehicle, the power output was increased to 700 horsepower (cv), setting a new record in this segment with an output of 234 horsepower per liter. In terms of aerodynamics, solutions derived from the 296 GT3 were taken and pushed to the extreme to achieve unprecedented downforce figures. These include the "S-shaped duct" (which draws air into the central radiator and exhausts it through the vents on the bonnet), the "swan-neck rear wing layout (another element inspired by the development of the 296 GT3)", and the A device that maximizes the stability of downforce generated in different trim conditions.

The braking system has also been completely redesigned. It's the first to feature the new "CCM-R PLUS" disc, which features technology derived from extreme track applications. New Pirelli tires developed specifically for the 296 Challenge also contributed significantly to improved performance. After its debut at the "2019 Finali Mondiali", the 296 Challenge set a record at the Mugello circuit approximately 2 seconds faster than its predecessor "488 Challenge Evo" which debuted in the 2020 season. From the early stages of development, the 296 Challenge discussed removing all hybrid components from the V6 powertrain, as in the 296 GT3. The electric motor and high-voltage battery have been eliminated, and the output of the twin-turbo V6 engine has been increased to 700 cv. This approach helps limit vehicle weight and overall unit complexity, which are fundamental factors in track driving.

Ferrari unveils '296 Challenge' race car with F1 technology

#cars#ferrari#ferrari f1#formula 1#scuderia ferrari#formula one drivers#formula one#296 Challenge#car

8 notes

·

View notes

Text

Get Premium Exhaust System Components for A Legendary Sound.

Want to get The Best Vehicle Exhaust System for your vehicle? Shop for top-quality vehicle exhaust system components online from the AutoPartsUSA store, get premium exhaust from top brands, and place your order. We will take care of everything and deliver it to you. Shop now at our website.

0 notes

Video

The M1A2 Abrams Main battle tank. - M1A2 (Baseline) : Production began in 1986 and entered service in 1992 (77 built for the US and more than 600 M1s upgraded to M1A2, 315 for Saudi Arabia, 218 for Kuwait). The M1A2 offers the tank commander an independent thermal sight and ability to, in rapid sequence, shoot at two targets without the need to acquire each one sequentially, also 2nd generation depleted uranium armor components.

- M1A2 SEP (System Enhancement Package) : Has upgraded third-generation depleted uranium armor components with graphite coating (240 new built, 300 M1A2s upgraded to M1A2 SEP for the USA, also unknown numbers of upgraded basic M1s and M1IPs, also 400 oldest M1A1s upgraded to M1A2 SEP)

- M1A2S (Saudi Package) : Saudi Arabian variant upgrade of the M1A2 based on M1A2 SEP, with some features, such as depleted uranium armor, believed to be missing (442 M1A2s upgraded to M1A2S).

- M1A2 SEPv2 : Added Common Remotely Operated Weapon Station as standard, color displays, improved interfaces, a new operating system, improved front and side armor with ERA (TUSK kit), tank-infantry phone as standard, and an upgraded transmission for better durability.

- M1A2C (SEPv3) : Has increased power generation and distribution, better communications and networking, new Vehicle Health Management System (VHMS) and Line Replaceable Modules (LRMs) for improved maintenance, an Ammunition DataLink (ADL) to use airburst rounds, improved counter-IED armor package, improved FLIR using long- and mid-wave infrared, a low-profile CROWS RWS, and an Auxiliary Power Unit (APU) under armor to run electronics while stationary instead of the engine, visually distinguishing the version by a small exhaust at the left rear. Prototypes began testing in 2015, and the first were delivered in October 2017. Fielding is expected to begin in 2020.

- M1A2D (SEPv4) : Under engineering development with delivery planned to start by 2020. The Commander’s Primary Sight, also known as the Commander’s Independent Thermal Viewer, and Gunner’s Primary Sight will be upgraded with 3rd Gen FLIR, an improved laser rangefinder and color cameras. Additional improvements will include advanced meteorological sensors, laser warning/detection receivers, directional smoke grenade launchers and integration of the new XM1147 multi-purpose (AMP) 120 mm tank round. The AN/VVR-4 laser warning receiver and ROSY rapid obscurant system have been trialed by the US Army for adoption on the Abrams tank and Bradley fighting vehicle.

- M1A2-K : Under development, unique variant for the Kuwaiti Army, slated to replace Kuwait's current M1A2 fleet.

(via The M1A2 Abrams Main battle tank. | - M1A2 (Baseline) : Prod… | Flickr)

13 notes

·

View notes

Text

What is an MOT?

https://easthybrid.com/mot-service/

An MOT test is a comprehensive examination of a vehicle's key components and systems to ascertain whether it meets the minimum legal standards for road use. It is a statutory requirement for most vehicles over a certain age, typically conducted annually.

2. Components Checked During an MOT:

Trained and certified technicians inspect various elements of the vehicle, including brakes, lights, steering and suspension, tires, exhaust system, seat belts, and overall structural integrity. Additionally, mot & service emissions are measured to ensure compliance with environmental standards.

3. Importance of Regular Tests:

Safety Assurance: The MOT test is a proactive measure to identify and rectify potential safety issues before they escalate. It ensures that crucial components are in proper working order, reducing the risk of accidents and breakdowns on the road.

Environmental Responsibility: The examination of emissions during a Mot Centre contributes to environmental sustainability. By ensuring that vehicles meet emission standards, the test aids in reducing harmful pollutants released into the atmosphere

2 notes

·

View notes

Text

The Future of Auto Engine Cleaning: Innovations in Dry Ice Blasting

In the ever-evolving world of automotive technology, innovation is the driving force behind improvements in engine performance, environmental sustainability, and overall driving experience. As engines become more advanced, so do the methods used to clean and maintain them. One of the most promising innovations on the horizon is "dry ice blasting in automobile" engine cleaning, a revolutionary approach that is set to reshape the future of auto maintenance. In this blog post, we will explore the latest developments and the potential of Dry Ice Blasting in the Automotive Industry.

Dry Ice Blasting in Car Engine

The Importance of Engine Cleaning

A clean engine is not just a matter of aesthetics; it's crucial for optimal performance and efficiency. Over time, engines accumulate dirt, grime, carbon deposits, and other contaminants that can negatively impact their function. Regular engine cleaning is essential to maintain fuel efficiency, reduce emissions, prevent damage, and extend the life of the engine. In this context, the emerging technology of dry ice blasting promises to be a game-changer.

Traditional Engine Cleaning Methods

Before diving into the innovative aspects of dry ice blasting, let's take a quick look at the traditional methods for engine cleaning:

Chemical Cleaning: Chemical solvents and degreasers are commonly used to dissolve and remove dirt and grime. However, these chemicals can be harmful to the environment and pose health risks to those handling them.

Abrasive Cleaning: Sandblasting or other abrasive methods involve blasting particles at the engine surface to remove contaminants. These methods can be effective but also risk damaging engine components.

Water-Based Cleaning: High-pressure water jet cleaning is used to remove dirt, but it can result in water waste and may not be suitable for certain engine parts.

The Rise of Dry Ice Blasting

Dry ice blasting is a cutting-edge cleaning method that leverages solid carbon dioxide (CO2) pellets. When these pellets are propelled at high speeds and impact the surface to be cleaned, they undergo a process known as sublimation, transitioning directly from a solid to a gas. This sublimation process creates mini-explosions on the surface, effectively dislodging and removing contaminants.

What Sets Dry Ice Blasting Apart?

The adoption of dry ice blasting in the automotive industry is driven by several key advantages:

Non-Arasive: Unlike traditional abrasive methods, dry ice blasting is non-abrasive and gentle on engine components. This non-destructive approach ensures that the engine parts remain undamaged.

Eco-Friendly: Dry ice is a byproduct of industrial processes, making it an environmentally friendly choice. It produces no secondary waste, chemical residue, or harm to the environment.

Efficient: Dry ice blasting is a highly efficient cleaning method, reducing labor hours and downtime for the vehicle, which can lead to cost savings.

Versatile: It can be applied to a wide range of engine components, from the engine block to exhaust systems, making it a versatile solution for engine cleaning.

Safety: Dry ice blasting eliminates the need for toxic chemicals, enhancing the safety of those involved in the cleaning process.

Long-Term Benefits: Regular use of dry ice blasting can help prevent future contamination, extending the life and efficiency of engine parts.

Current Innovations in Dry Ice Blasting

Dry ice blasting in the automotive industry is continually evolving, with several noteworthy innovations taking place:

Precision Cleaning: Advanced nozzle designs and control systems allow for more precise cleaning, ensuring that contaminants are removed without affecting the underlying surface.

Integration with Robotics: The use of robots for dry ice blasting is gaining traction. This automation allows for consistent and efficient cleaning processes in manufacturing plants and repair shops.

Ergonomic Design: Improved ergonomic designs of dry ice blasting equipment enhance the comfort and safety of operators during the cleaning process.

Smart Monitoring: Real-time monitoring and data analysis during the cleaning process are becoming more prevalent. This data can help optimize the cleaning process and predict maintenance needs.

Enhanced Portability: Smaller, more portable dry ice blasting units are being developed, making it easier to access and clean hard-to-reach areas in engines.

The Future of Auto Engine Cleaning

So, what does the future hold for dry ice blasting in the automotive industry?

Increased Adoption: As awareness of the benefits of dry ice blasting spreads, it is expected that more automobile manufacturers, repair shops, and enthusiasts will adopt this innovative cleaning method.

Wider Range of Applications: Dry ice blasting is likely to be used for various automotive applications, such as paint removal, decarbonization, and the removal of other contaminants beyond dirt and grime.

Collaboration with Automation: The integration of dry ice blasting with automation, including robotics, will become more commonplace in manufacturing plants and maintenance facilities.

Enhanced Efficiency: Continuous advancements in nozzle design and automation will make dry ice blasting even more efficient and reliable.

Environmental Responsibility: As environmental regulations become more stringent, the automotive industry's commitment to sustainability will drive the adoption of eco-friendly cleaning methods like dry ice blasting.

Case Studies: Success Stories

Let's explore a couple of success stories that highlight the transformational impact of Dry Ice Blasting in Automotive Industry:

Case Study 1: An automobile manufacturing plant introduced dry ice blasting in their engine cleaning process. The result was a significant reduction in emissions, thanks to the elimination of toxic chemicals. This not only aligned with their environmental goals but also improved worker safety.

Case Study 2: A classic car restoration workshop integrated dry ice blasting into their restoration projects. This approach allowed them to restore vintage engines to their original glory without compromising their authenticity. It attracted environmentally conscious customers seeking sustainable restoration methods.

The future of auto engine cleaning is poised for transformation, and dry ice blasting is at the forefront of this change. As the automotive industry continues to embrace environmentally responsible practices, innovations in dry ice blasting will play a pivotal role. This technology is not only an effective cleaning method but also a sustainable and eco-friendly solution that promises to shape the future of engine maintenance in the automotive world. The road ahead looks cleaner, more efficient, and in harmony with our environment, thanks to dry ice blasting.

#dry ice#dryiceblasting#dryicecleaning#amsdryice#cleaning#cars#automobiles#carservice#car service near me#automotive

3 notes

·

View notes

Text

Industrial Applications of Mild Steel Pipes

Mild Steel (MS) pipes are widely used in industrial applications due to their exceptional strength, durability, and affordability. As a reliable MS Pipe dealer in Gujarat, Tube Trading Co., understands the importance of these versatile pipes in a range of sectors. In this article, we will explore the industrial applications of MS pipes and highlight their significance as a Square pipe distributor in Vadodara.

Construction Industry:

The construction industry heavily relies on the utilization of mild steel pipes for various applications. These pipes are commonly employed in plumbing systems, water distribution networks, and sewage lines. The corrosion resistance and durability of MS pipes make them particularly suitable for underground installations. Moreover, they are extensively used for structural purposes in the construction of frameworks for buildings, bridges, and other infrastructure projects. The square-shaped MS pipes supplied by Tube Trading Co. - an excellent Square pipe distributor in Vadodara, make them highly suitable for creating sturdy supports, columns, and frames, enhancing the overall strength and stability of structures.

Oil and Gas Industry:

The oil and gas industry heavily relies on mild steel pipes for efficient resource transportation. These pipes are crucial for conveying petroleum products, natural gas, and various chemicals. The strength, reliability, and cost-effectiveness of MS pipes make them an excellent choice for pipelines in the industry. They possess the ability to withstand high-pressure applications, making them suitable for both onshore and offshore operations. The most trusted and noteworthy MS Pipe dealer in Gujarat - Tube Trading Co. caters to the demand for quality pipes in the oil and gas sector, ensuring the seamless flow of resources and contributing to the industry's overall productivity.

Automotive Manufacturing:

MS pipes are widely used in the automotive sector for manufacturing exhaust systems and chassis components. The excellent weldability of MS pipes allows for easy fabrication, enabling the production of customized exhaust systems that meet specific performance requirements. Additionally, the durability and strength of MS pipes make them suitable for creating sturdy chassis components, ensuring the safety and structural integrity of vehicles.

Agriculture and Irrigation:

Mild steel pipes are an integral part of irrigation systems in the agriculture sector. These pipes are used to transport water from sources such as wells, rivers, or reservoirs to fields for crop irrigation. MS pipes are durable and resistant to harsh environmental conditions, making them suitable for both above-ground and underground installations. They are also utilized in the construction of fencing structures, greenhouses, and enclosures for livestock. Square pipes, distributed by Tube Trading Co. - a reliable MS Pipe dealer in Gujarat, are commonly employed to create robust support frames for agricultural structures, ensuring their stability and longevity.

Manufacturing and Engineering:

Mild steel pipes are widely utilized in the manufacturing sector for diverse purposes. They play a crucial role in the fabrication of machinery, equipment, and conveyor systems. MS pipes are employed as conduits for the efficient transport of fluids, gases, and other materials within manufacturing plants. Due to their strength and ductility, these pipes are reliable for conveying compressed air, hydraulic fluids, and various chemicals. Furthermore, in the automotive industry, MS pipes find extensive usage in the production of exhaust systems, roll cages, and chassis components, thanks to their durability and affordability.

Infrastructure Development:

MS pipes play a significant role in infrastructure development projects. They are used for the construction of bridges, flyovers, and elevated highways, providing structural support and facilitating the transportation of people and goods. MS pipes are also employed in the installation of underground utility networks, including water supply, sewage, and gas pipelines.

Choosing the right-sized mild steel pipes for your project:

Choosing the right-sized mild steel pipes for your project is crucial to ensure proper functionality, structural integrity, and cost-effectiveness. Let’s explore some key factors to consider while choosing the right-sized MS pipes:

Flow Requirements: Determine the flow rate or volume of fluids or gases that will pass through the pipe. Calculate the required pipe diameter based on the desired flow velocity and pressure drop. This will help you choose a pipe size that can handle the anticipated flow without causing excessive pressure loss.

Load-Bearing Capacity: Assess the load-bearing requirements of your project. Consider the weight or load that the pipe will need to support, whether it's structural loads, machinery, or equipment. Larger-diameter pipes with thicker walls generally have a higher load-bearing capacity, providing greater strength and stability.

Material Compatibility: Ensure that the chosen mild steel pipe is compatible with the fluids or gases that will be conveyed. Consider factors such as corrosion resistance, chemical compatibility, and temperature limitations. Mild steel pipes are generally suitable for a wide range of applications, but if you anticipate exposure to corrosive environments, you may need to consider additional protective coatings or alternative materials.

Installation Considerations: Evaluate the available space and installation requirements. Consider factors such as the pipe's length, flexibility, and ease of joining. Determine whether you need straight lengths or require bends, fittings, or connectors to navigate through the project site. Ensure that the chosen pipe size can be accommodated within the available space without hindering the overall functionality of the system.

Standards and Regulations: Comply with industry standards and regulations governing pipe sizing for specific applications. Different industries and regions may have specific guidelines regarding pipe size selection. Familiarize yourself with relevant codes and standards to ensure compliance and to guarantee the safety and efficiency of your project.

Cost Considerations: Evaluate the cost implications associated with different pipe sizes. Larger-diameter pipes with thicker walls tend to be more expensive than smaller ones. Consider the balance between cost and performance to ensure that you select a pipe size that meets your project requirements while optimizing your budget.

Consultation and Expert Advice: If you are uncertain about the appropriate pipe size for your project, it is advisable to consult with experienced engineers, contractors, or MS pipe dealers. They can provide valuable insights and help you make an informed decision based on the specific needs and constraints of your project.

Final Thoughts:

Mild steel (MS) pipes have become indispensable in numerous industrial applications due to their versatility, reliability, and cost-effectiveness. In Gujarat, a state experiencing rapid industrial growth, Square pipe distributors in Vadodara serve as crucial suppliers, fulfilling the demand for quality pipes, including square pipes. The construction industry benefits from mild steel pipes for plumbing and structural applications, while the manufacturing sector relies on them for machinery fabrication. In agriculture, these pipes find extensive usage in irrigation systems and the construction of agricultural structures. Furthermore, the oil and gas industry heavily depends on MS pipes for efficient resource transportation. The widespread utilization of mild steel pipes underscores their importance in driving industrial development and infrastructure growth.

#distributor#Jindal pipes#steel industry#steel companies#industrial#seamless pipes#piping material#plumbing industry#construction structure#manufacturer#construction sites

7 notes

·

View notes

Photo

New Post has been published on https://www.vividracing.com/blog/rennline-991-2-carbon-fiber-aero-kit-w-oem-style-fit/

Rennline 991.2 Carbon Fiber Aero Kit w/ OEM Style Fit

Are you looking to take your Porsche 991.2’s aerodynamic performance to the next level? Do you enjoy pushing your Porsche 991.2 to the limit, on the road and track? The new Rennline aero kit is here to help you do just that. Rennline as brand specializes in manufacturing performance parts for high-end sports cars such as Porsche, Audi and BMW. Their recent aero kit is guaranteed to make your 991.2 stand out from the crowd!

This kit is manufactured using carbon fiber, and the full kit includes side skirts, front lip and rear diffusers. There are several ways that your Porsche 991.2 will benefit from this full body kit upgrade, and so once installed you will see improvements in:

Stability: Improved aerodynamics can enhance the overall stability of the Porsche 991.2, especially at higher speeds..

Handling: Aerodynamic upgrades, such as spoilers and diffusers, can contribute to better handling by increasing down force on the car. Which in turn improves traction and grip, particularly during cornering.

Efficiency: Streamlining the airflow around the vehicle helps reduce aerodynamic drag. This, in turn, can lead to improved fuel efficiency and potentially higher top speeds..

With the Rennline Carbon Fiber Aero Kit, you will experience an enhanced driving experience on the road and in your track adventures. In addition to those benefits, by improving the aerodynamics performance with this system, you will also aid in better cooling for the engine and other components, ensuring optimal performance under various driving conditions.

Features

Hand-laid carbon fiber construction

High gloss finish with UV and heat protection

Designed from the ground up using state of the art 3D scanning technology

OEM fit and finish

Click Here to Buy the Rennline Carbon Fiber Aero Kit for Your Porsche 991.2

Kit Includes:

Front Lip – 991.2 C2/C2S/C4/C4S/Targa 4/Targa 4S

Side Skirts – 991 C2/C2S

Rear Diffuser – C2/C2S/C4/C4S/GTS/Targa/Turbo – With

Sport Exhaust

Fitment:

Porsche 991.2 C2/C2S/C4/C4S/Targa 4/Targa 4S

Porsche 991 C2/C2S

Porsche C2/C2S/C4/C4S/GTS/Targa/Turbo

If you have any questions about Rennline or you need new Aero body for your Porsche 991.2, please do not hesitate to contact us. You can reach us by phone at 1-480-966-3040 or via email at [email protected].

#porsche#Porsche 991.2 aero kit upgrade#Porsche 991.2 upgrades#rennline#Rennline kits#Rennline Porsche aero kit

2 notes

·

View notes

Text

A Closer Look at the Mustang EcoBoost: How Does it Achieve High MPG?

The Ford Mustang has been an emblem of American muscle cars for generations, celebrated for its power and performance. However, the introduction of the Mustang EcoBoost MPG brought a remarkable shift to the iconic pony car's legacy by placing a significant emphasis on fuel efficiency. In this article, we will take a closer look at the Mustang EcoBoost and uncover the secrets of how it achieves high miles per gallon (MPG) without sacrificing its exhilarating driving experience.

The Turbocharged Heart of the Mustang EcoBoost

At the heart of the Mustang EcoBoost's impressive fuel efficiency is its innovative 2.3-liter inline-four-cylinder engine. Unlike the traditional V8 engines that have dominated the Mustang lineup, the EcoBoost boasts a turbocharged powerplant. Here's how this turbocharged engine contributes to high MPG:

Turbocharging and Direct Injection

The turbocharger is a small but powerful device that compresses the air entering the engine, allowing more air to be forced into the combustion chamber. This process, known as forced induction, significantly increases the engine's efficiency by providing more oxygen for combustion. Coupled with direct fuel injection, where fuel is sprayed directly into the combustion chamber, the Mustang EcoBoost's engine can produce more power from less fuel.

Smaller Displacement, Better Efficiency

The smaller displacement of the four-cylinder engine means less internal friction and energy loss compared to larger V8 engines. Smaller engines inherently require less fuel to operate, and this plays a pivotal role in achieving high MPG. The Mustang EcoBoost's engine achieves a fine balance between power and efficiency.

Variable Valve Timing

The EcoBoost engine features advanced variable valve timing, allowing it to optimize the timing of intake and exhaust valve openings. This technology ensures that the engine operates at peak efficiency across a wide range of speeds and loads. It adapts to driving conditions to provide both power and fuel savings.

Aerodynamic Efficiency

Another key factor contributing to the Mustang EcoBoost's high MPG is its aerodynamic design. While the Mustang is celebrated for its classic styling, Ford engineers have incorporated modern aerodynamic elements to enhance efficiency:

Sleek Body Profile

The Mustang EcoBoost features a sleek body profile designed to minimize wind resistance. This streamlined shape helps the car cut through the air more efficiently, reducing the energy required to maintain speed. This is especially beneficial during highway driving, where the Mustang can achieve optimal fuel economy.

Active Grille Shutters

The Mustang EcoBoost incorporates active grille shutters that automatically open and close to control airflow to the engine. When additional cooling is not required, these shutters close to reduce drag, making the vehicle more aerodynamic. When more cooling is needed, such as during intense acceleration, the shutters open to provide maximum airflow.

Technological Advancements

The Mustang EcoBoost is not only about its engine and design; it also leverages advanced technologies to further improve fuel efficiency:

Start-Stop System

The Mustang EcoBoost is equipped with a start-stop system that automatically shuts off the engine when the vehicle comes to a stop and restarts it when you release the brake pedal. This feature eliminates unnecessary idling, saving fuel in city traffic and stop-and-go situations.

Driving Modes

The Mustang EcoBoost offers different driving modes, including an "Eco" mode. In this mode, the engine and transmission are adjusted to prioritize fuel efficiency. While it may reduce the car's responsiveness slightly, it's a valuable tool for conserving fuel on long drives or in heavy traffic.

Lightweight Materials

To further enhance fuel efficiency, the Mustang EcoBoost incorporates lightweight materials in its construction. Components like aluminum are used to reduce overall weight without compromising structural integrity. A lighter vehicle requires less energy to accelerate and maintain speed, thus improving MPG.

Conclusion

The Ford Mustang EcoBoost represents a remarkable evolution of the iconic muscle car, combining power and performance with a focus on fuel efficiency. The innovative turbocharged engine, aerodynamic design, and advanced technologies work in harmony to deliver impressive MPG figures. The Mustang EcoBoost demonstrates that performance and fuel efficiency can coexist, setting new standards for the sports car category. As we move towards a more environmentally conscious future, the Mustang EcoBoost showcases the adaptability and sustainability of a legendary American classic.

2 notes

·

View notes